Micro-Perforations

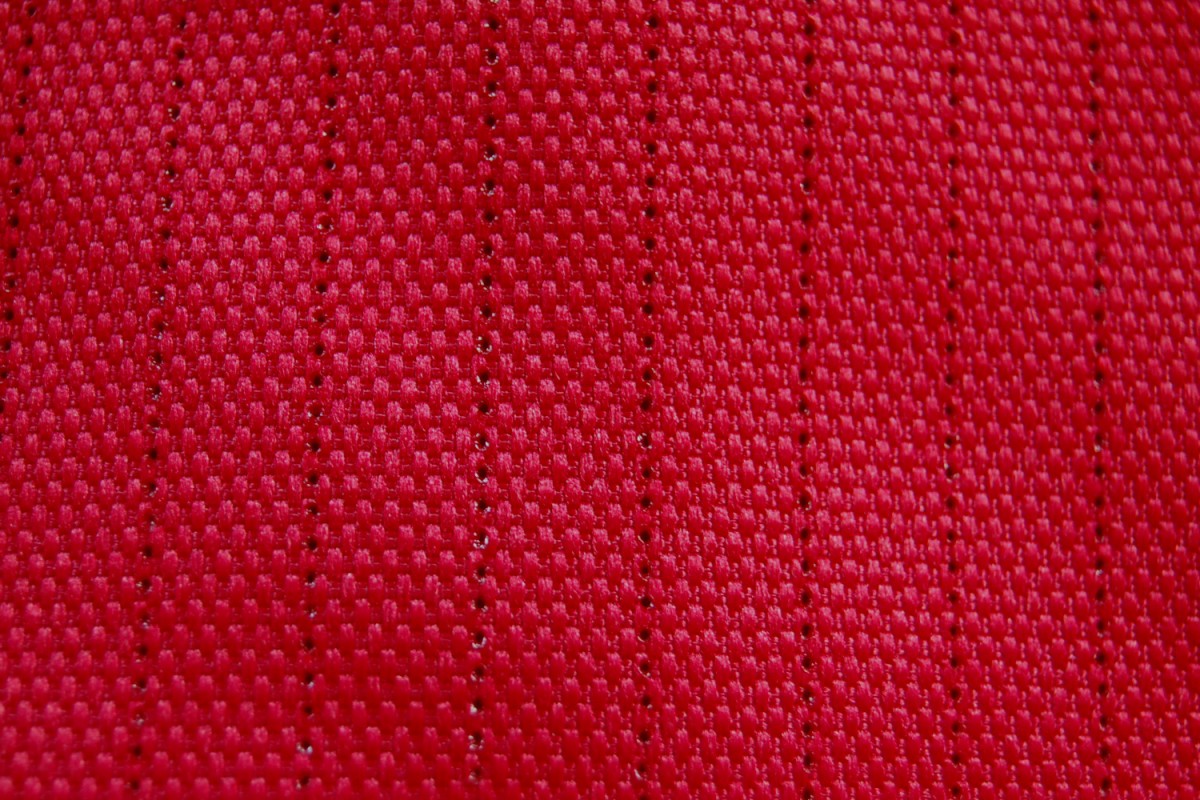

Micro-Perforations are 0.2mm laser cut holes. The number of holes is calculated precisely to match the air volume and pressure available. This gives Micro-Perforations several advantages over Permeable Material Competitors.

(1) The air delivery is based upon an accurate, calculated and laser cut diffusion area (rather than an approximate permeable value per m2) meaning more accurate air and pressure control and more efficient operation of the AHU plant

(2) Micro-perforations don’t allow the same level of dust build up within the duct as we’re not squeezing the air between loose fibres – meaning less blockage and lower operating pressures over time leading to higher performance and AHU plant efficiency.

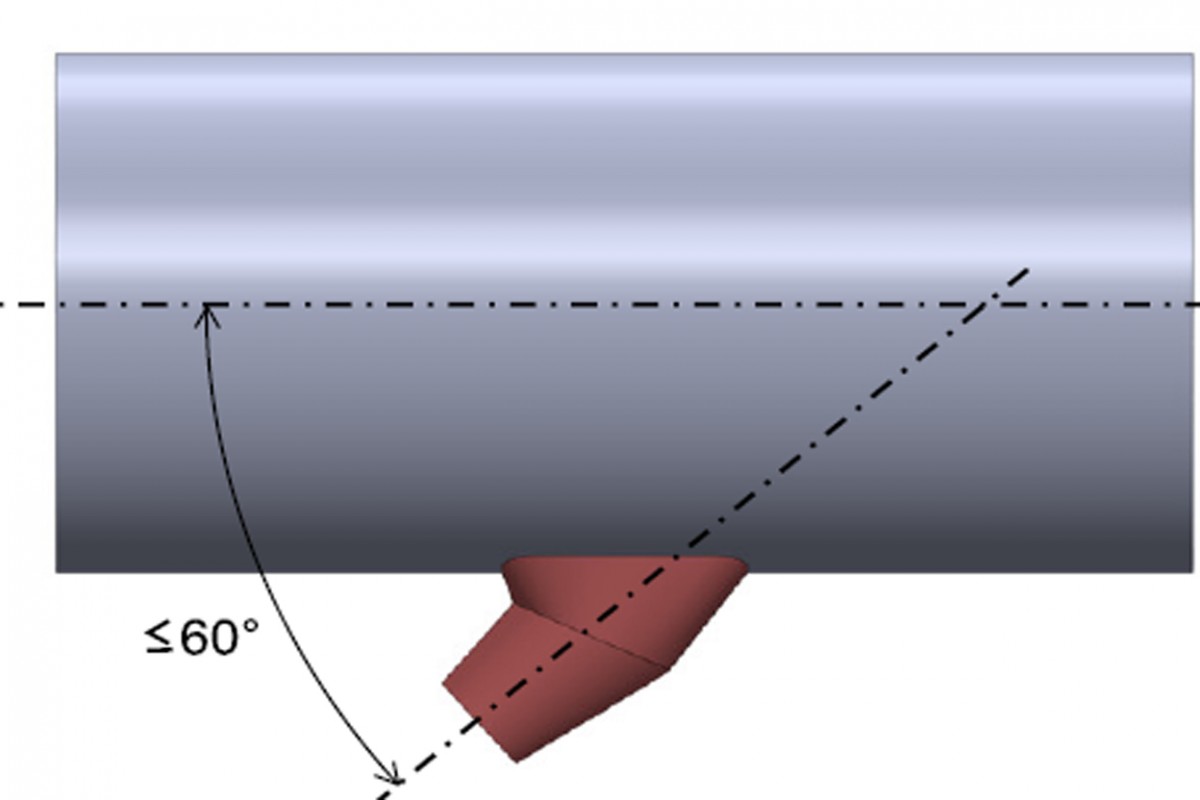

(3) We can place the micro-perforations anywhere upon the duct circumference. This allows us to create a variety of low velocity air patterns and avoids the ‘dumping’ of air immediately below the duct associated with permeable only Textile Diffusers when cooling with a wide temperature difference.

We use Micro-Perforations mainly for cooling and for make up air / tempered fresh air.

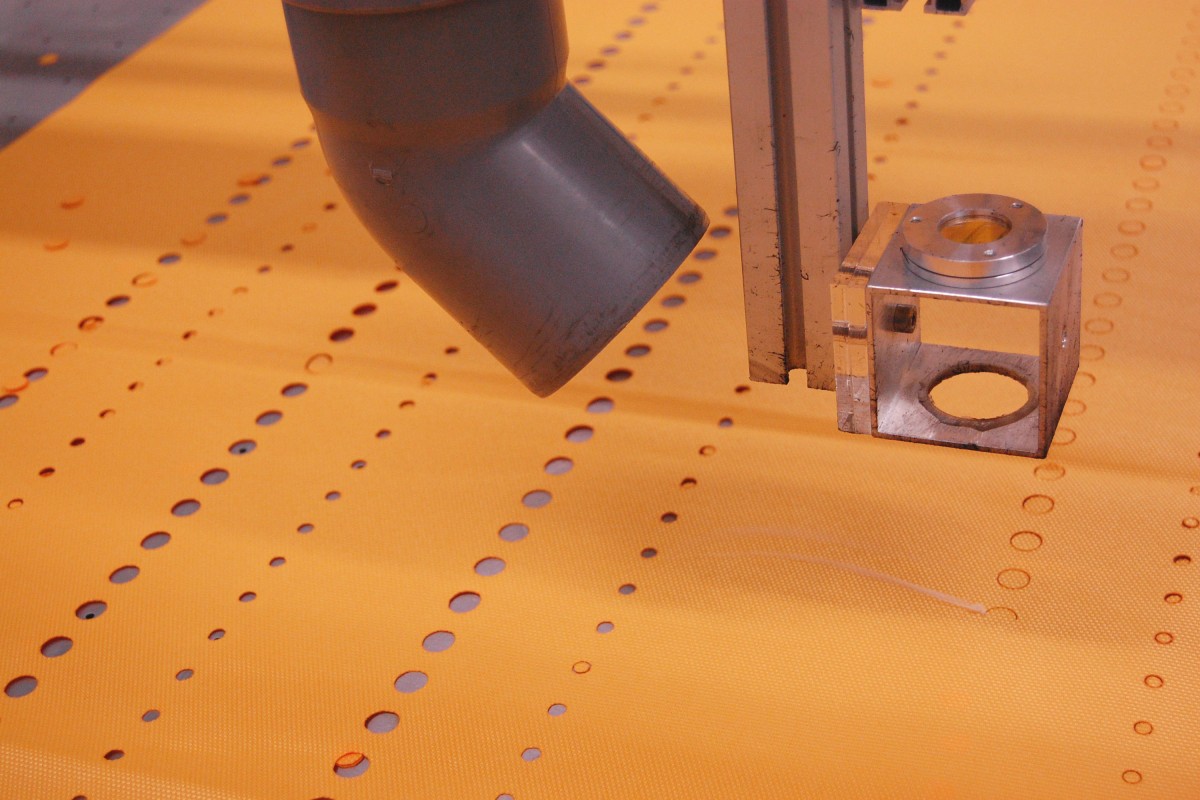

Laser Cut Perforations

Laser Cut Perforations start at 4mm diameter and are the ultimate in diffusion flexibility as there is an unlimited variety of diffuser positions and air patterns achievable. We can laser cut any perforation diameter, in any position on the duct, in any number of rows, with a variable gap between rows and a variable gap between the perforations in the row….. We can create systems with different throw characteristics, systems that spread air in multiple directions simultaneously, systems that entrain more ambient air for mixing or less if required. The possibilities are limited only by physics (air pressure and density).

Laser Cut Perforations are used in majority of our cooling / heating / fresh air applications.

Small Fabric Nozzles

Small Fabric Nozzles are designed to throw air in a focussed narrow air pattern in a specific direction, typically over a longer distance than Laser Cut Perforations. Prihoda Fabric Nozzles are available in 20mm, 30mm and 40mm diameters each giving different throw characteristics.

It’s typical for Nozzles to entrain less ambient room air than Laser Cut Perforations (but this is not exclusive as there are low entrainment patterns available for Laser Cut Perforations too).

Fabric Nozzles are made from the exact same Fabric as the duct, same material and same colour. They are therefore Flame Retardant (unlike the Plastic Nozzles from our competitors) and as they are sonic welded to the fabric there’s no chance of them dropping off either. Fabric nozzles are also lighter than the plastic alternatives and cause less abrasive damage during duct washing.

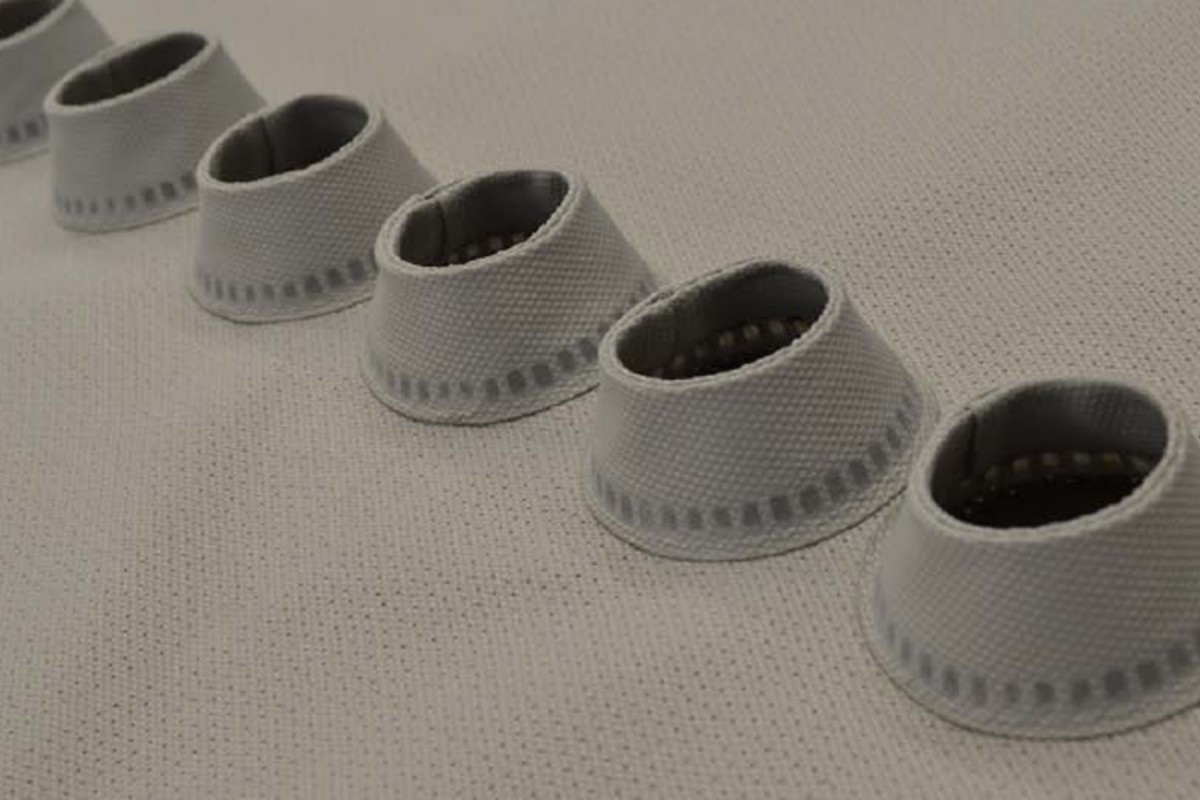

Large Fabric Nozzles

Large Fabric Nozzles start at 80mm diameter and are designed for very long throw applications such as High Bay Warehousing, Sports Halls and Chilled Storage for example.

The size of the nozzle allows us to offer various options for increased flexibility for example we can fit Dampers, allowing customers to regulate or even close specific Large Fabric Nozzles. We also offer an option to make the Nozzle directional, by loosening or tightening a number of cords on the internal part of the Nozzle one can change the Nozzle position significantly to alter the pattern or direction of the supply air.

Large Fabric Nozzles are also made from the same material as the duct and are also therefore Flame Retardant and match the same exact colour as the duct. The Nozzles are sewn on to the duct and are significantly lighter than the nearest plastic alternative meaning the fabric around the nozzle is under less tension and therefore suffers less distortion than that the large plastic alternative (requiring less system pressure to achieve an acceptable aesthetic finish to the duct).